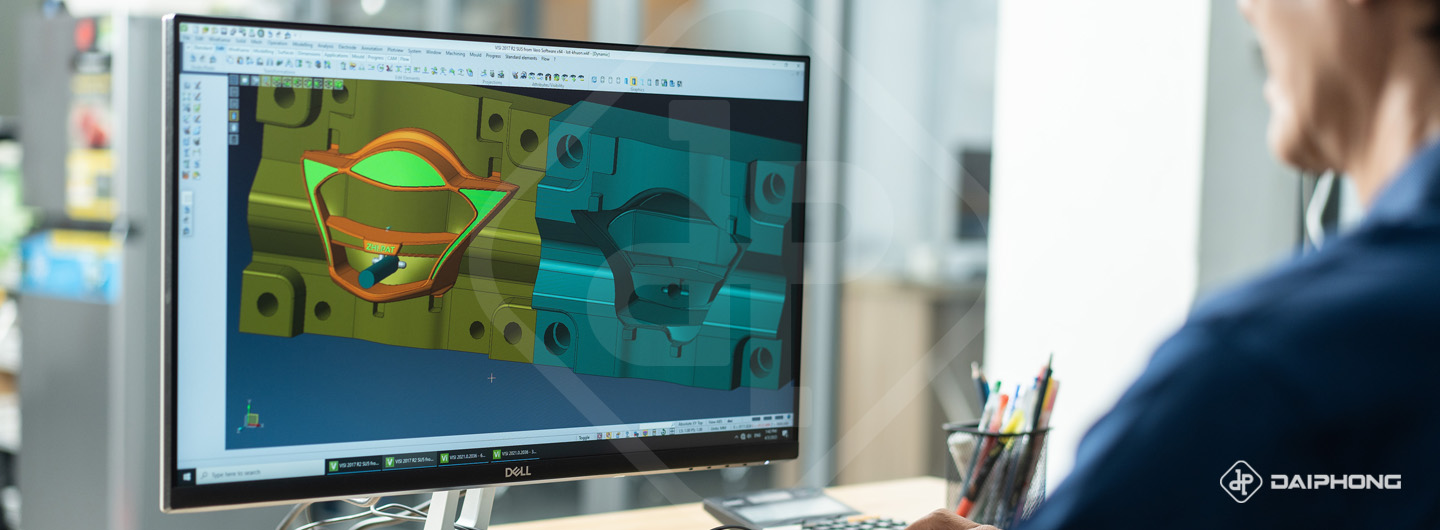

From Concept to CAD Drawing

At Dai Phong, our mold design process seamlessly combines expertise, knowledge, and cutting-edge technology. We understand that achieving top-quality plastic products necessitates a meticulously planned mold design. Dai Phong offers specialized mold design services, ensuring your molds not only meet every requirement but also achieve the pinnacle of quality.

We accept data from a multitude of sources, whether it originates from the customer’s initial concept, 2D/3D mockups, or existing technical drawings. Your only task is to provide us with files in formats like STEP/STP, IGS, XT, and we will take care of the rest. We guarantee that our mold designs will satisfy all your specifications and reach high quality.