=

INDUSTRIAL DESIGN

Help businesses maintain a competitive edge in a volatile market with the highest standards of creativity and business acumen.

We believe that every great product starts with a creative idea. The idea development process is an exciting and important part, where we turn your ideas into reality. Our design team at DAI PHONG has the insights to bring ideas to life, meet the real-world needs of customers, and be in line with the brand value of the product.

Dai Phong has extensive experience designing industrial designs for products in the electrical industry, toys, consumer products, and the motorbike and car industry.

Through practical experience, listening, 1-1 group discussion, understanding the actual needs & applications of the product and using 3D technology solutions are the foundation of effective product design.

Product models with well-thought-out designs are the main competitive tool in the battle for market share and help strengthen customers’ brands. We use the latest technology for design, visualization, realistic 3D prototyping to create designs that suit the tastes of the market.

Using industry knowledge and understanding the product’s own problems, Dai Phong provides simple and convenient product design solutions that are perfected down to every small detail, which are outstanding advantages in Dai Phong product design.

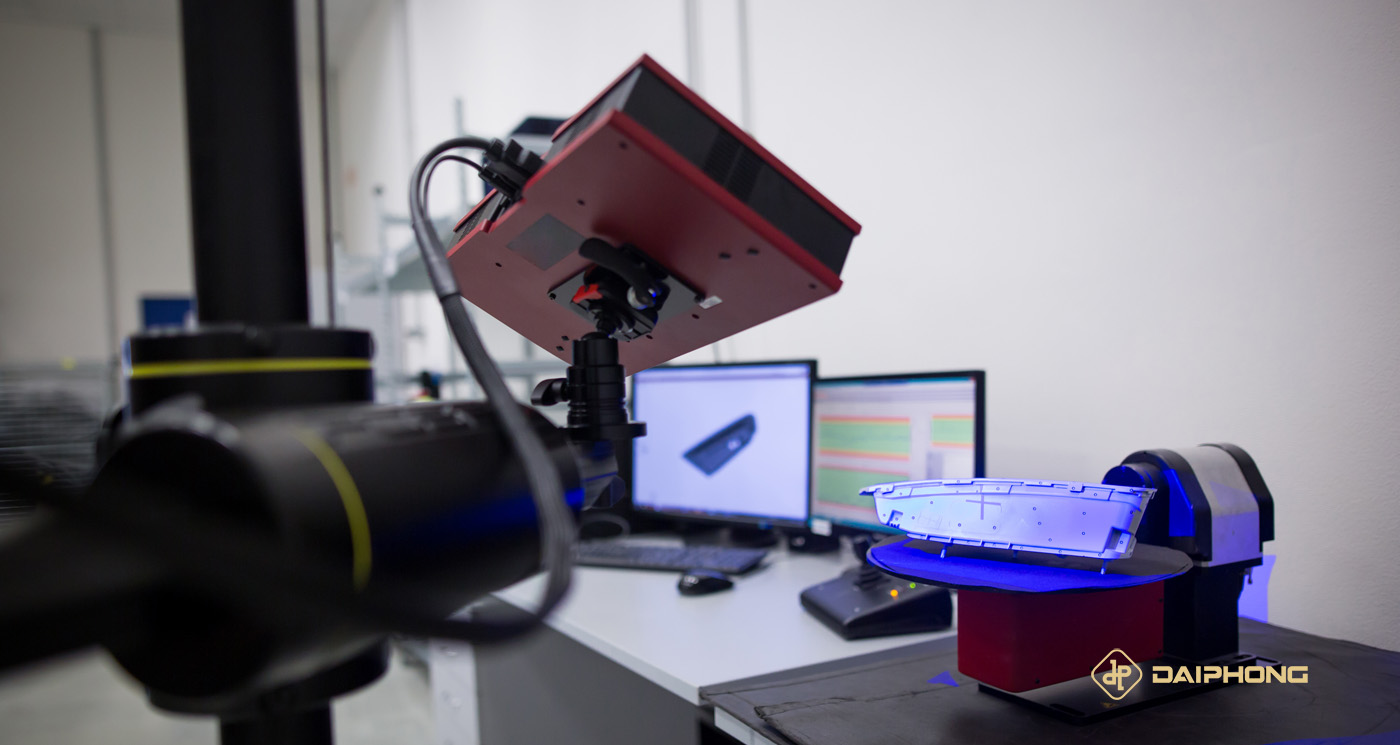

We employ traditional techniques in conjunction with specialized software in 3D technology to create CAD models. The software we use includes Solidworks, Creo, Pro-Engineer, SketchBook Pro, and Photoshop.

Dai Phong welcomes the opportunity to collaborate with you in turning these ideas into products that bring inspiration and practicality. We are committed to supporting you at every stage of the product development process, from initial concepts to mold design and the production of completed products.

ISO 9001 – 14001 – 45001 Management System

At Dai Phong, ensuring product quality and safety is paramount. We have implemented a rigorous quality control system that spans the entire supply chain, from our suppliers’ factories to our own production facilities. This system includes quality control for incoming raw materials, monitoring each production stage, overseeing the quality of finished products, and managing product storage in our warehouse. Our commitment to quality is unwavering, and our products go through a meticulous inspection process at every step. From the design phase to production, dedicated project engineers oversee each stage.

Our team of experienced engineers has over 25 years of experience in the field of plastic injection mold design. We provide mold design services for all types of plastic products…

Xem chi tiết